SR-UVC300 Full automatic UV hot melt adhesive label rotary bar coating machine

Configuration

Full automatic convert unwinder & rewinder.

Full automatic cutting function unwinder & rewinder.

Frequency conversion motor for unwinder & rewinder

24hrs running needn't stop.

Automatic process guiding system.

Constant tension control.

PLC touch screen problem, Siemens brand.

Length automatic control.

Adhesive pressure testing before filter and automatic alarm system.

UV unit IST brand, 1-6 sets lamp(depends on speed request)

Bigger diameter cooling roller

UV adhesive melting drum & melting tank

Equipment introduction

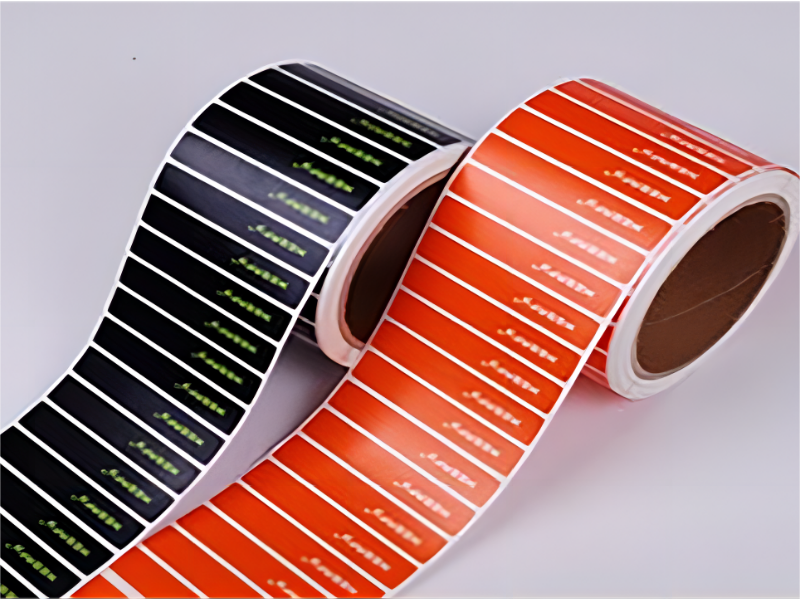

Application for PET/OPP film label, paper label or other high grade quality label product, with coating lamination.

Coating precision less than 6%. Die head is R & D by ourselves, structure, runner and precision up to International brand, special steel structure, rotary bar is international brand.

Die head angle could adjust, front & back, up & down movement.

Melting tank adhesive pump control adhesive pressure.

PLC touch screen controls system, could adjust adhesive gsm and coating width, all data show from it.

Rotary bar coating technology adhesive surface smooth, clear, no line, could be used on less adhesive product.

UV with adhesive drum unit melting, UV cure lamp, IST brand.

Big cooling roller for UV lamp position.

UV and hot melt PSA all could be used.

Equipment easy operate, raw material roller and end product roller position could change automatic needn’t stop.

Electric heating replace traditional oil heating, prevent roller inside carbonation problem.

Rotary bar international brand, wear resistance.

All process will be tested before shipment.

More than 23 years experience in equipment design.

Cost effecient solution for client hot melt adhesive coating machine request.

Application